Things to Consider When Choosing a Butt Hinge

Sampling and Testing

Want free butt hinge engineering samples? Sure! We know the value of prototyping and testing, and we strive to fill reasonable design sample requests quickly. Building a prototype shouldn't have to be a major expense and an engineering analysis of a prototype is usually the best way to confirm that you have selected a safe and effective product for your application. Working with the right supplier is the key to the success of your design process and you've already made a great choice with Guden, the hardware experts. With almost 100 years of experience, the samples, information and advice you can get from us can be priceless in getting your prototype off the ground and onto the production floor.

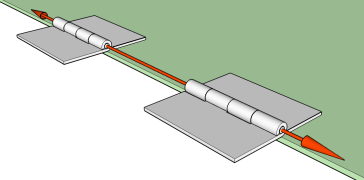

Alignment

Butt hinges can provide a different look than continuous hinges but require careful pin alignment for smooth operation. Be sure to account for alignment in your plans.

Leaf Material and Thickness

| • Plain Steel - affordable |

| • Stainless Steel - corrosion resistant |

| • Aluminum - lightweight |

Plain steel, type 302/304 stainless steel, type 316 stainless steel and type 5052 & 3003 aluminum are the

most popular material choices for a butt hinge. It is also common to have the hinge material match the material of the cabinet or box.

For material thickness, a good starting point is to select the same thickness as the enclosure. If the enclosure has some unusual weight

distribution, or a high or low door loads you may want to increase or possibly decrease the thickness.

Pin Size

There are usually only 1 or 2 choices of pin diameter for a given material thickness. As a general rule of thumb, the strongest hinge is one where the pin diameter is about twice the material thickness. The listings below are some of the most popular methods for pin retention, but you can also choose no retention at all for a loose pin, but you risk the pin just falling out of the hinge.

Pin Retention

| • Staked Pin - the knuckle is lightly punched to grip the pin |

| • Coined Pin - the pin is flattened, then forced in, to grip tightly |

| • Pin Spun Both Ends - the pin is machined to make a cap on both ends |

| • Pin Welded in Place - the pin is welded in place to an end knuckle |

| • Knuckle Rolled Tight for Retention - the specially tight knuckle holds the pin |

With or Without Mounting Holes

| • no holes, for welding |

| • standard through holes or slots |

| • standard countersunk holes |

| • custom hole or slot sizes and patterns |

| • custom threaded inserts |

The majority of hinges without holes are mounted by welding, but for easier mounting, many hinges are supplied with either holes, slots or custom threaded inserts or studs. Various standard hole patterns are readily available and just about any hole pattern you would require can also be supplied. Keep in mind that some non-standard patterns may require a tooling charge.

Custom Bends / Cuts / Swages

Don't forget that if you plan to modify the hinge, it might be cost effective to have the supplier do the custom operations for you. In addition to holes, slots and plating, hinges can be cut to length, bent, swaged, offset, and trimmed - nearly anything is possible. Simply provide us with a dimensional drawing to get a price quote.

Finish

| • Chemical Conversion | • Degrease | • Powder-coat |

| • Anodize | • Electro-Galvanize | • Polish |

| • Black Oxide | • Electropolish | • Passivate |

| • Burnished | • Nickel | • Zinc |

| • Chrome | • Paint | • NADCAP |

One of the last decisions to make on your hinge is the finish. Often your butt hinge will be finished along with the rest of your assembly, but if needed, Guden can supply the hinge with your specified finish. Most butt hinges are in stock without a finish, and we also have a line of electro-polished stainless butt hinges suitable for the marine industry or any application that needs a corrosion resistant hinge with a bright shiny finish.

Considering a Butt Hinge for your application? Click here to see our standard Butt hinges.