Custom Hinge Selection Tool

Bend - Swage - Offset : Reverse Assemble

Normally, hinges are assembled so that both leaves are on the same side of the pin.

However, Guden can supply the hinge with the leaves assembled on opposite sides of the pin for what is called a reverse assemble. Literally, the pin is extracted, one leaf is reversed, and the pin is reinserted.

This configuration is advantageous if you require an offset between the leaves but do not want to swage the leaves which can slightly lower the durability and strength of the material.

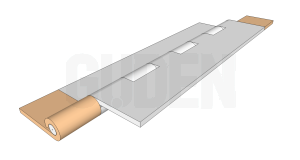

If the starting hinge has an even number of knuckles (as most standard length hinges do), there will be one knuckle of waste when reverse assembling, shown here in color. The excess is cut off.

Reverse Assembly has the disadvantage of being slower and more expensive than "swage to reverse" operation. This is because it requires considerable manual work, and if the pin is retained it may be difficult to remove, and the issue of extra waste and cutting described above.