Custom Hinge Selection Tool

Bend - Swage - Offset : Leaf Bending

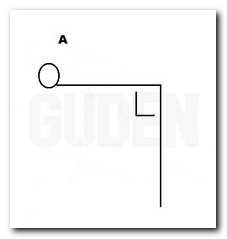

One or both of the hinge leaves can be bent so the hinge can be mounted around the side of a door or frame. The most popular configuration is a 90° bend, but the bend form can be at almost any angle depending on the thickness of the material. In thicker materials, it's sometimes not possible to make such an acute angle.

Bends can be made at any part of the leaf, except very close to the barrel because there is not enough leaf surface to hold the hinge in place while the rest of the leaf is bent. In order to bend the leaf, a press needs to come down and hold the leaf surface while another press forces down the rest of the leaf to form the bend.

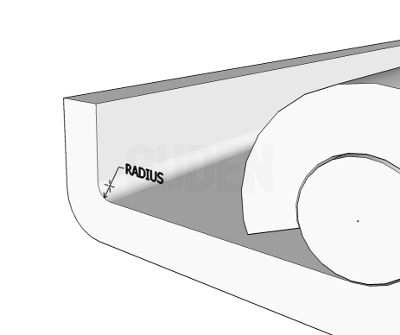

Bend Radius: The two sections of the bent leaf don't meet at a sharp corner. For example, the corner at which a 90° bend meets, on close inspection, is really rounded. This roundness is the bend radius, measured from the phantom circle center point of the bend.

Any number of bends can be done to a hinge of course with space permitting. One leaf or both leaves can have multiple bends to accomodate almost any configuration needed.

During the bending process a hinge leaf will stretch the width dimension slightly, adding approximately the thickness of the material to the overall width. If you started with an .060 leaf and a 1.00" leaf width, after bending the width would be approximately 1.06". If a specific leaf width is required, you would need to trim down the leaf, or start with a custom coil width so that the additional bending width growth is absorbed into the overall final width dimension.