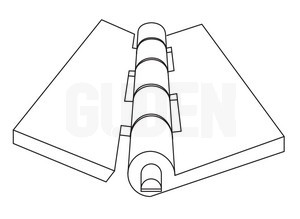

Custom Hinge Selection Tool

Pin Retention : Coined Pin

The coining process involves flattening a small portion of one end of the pin so it is larger in diameter than the pin itself, but not overly large that it would never be able to be driven into the hinge curl.

Starting with the unflatted end, the pin is inserted into the curl, then the flat portion that prevents it from sliding right in is driven forcibly into the curl. This extreme tight fit prevents the hinge pin from falling out, but it can be driven out from the other end with some force.